Most optical components are lenses. Lenses come in many forms and sizes, including convex, concave, cylindrical, and aspherical. Lenses are coated in a vacuum chamber while placed on a fixture or planetary rotating mount.

Due to the nature of the vacuum deposition process, it is impossible to measure the actual transmittance or reflectance of a lens in real time. Therefore, a parafilm is always used for process monitoring. However, the coating on the lens is often different from the coating on the parafilm. For many applications, it is critical to know the transmittance of the real lens. The actual optical performance can usually only be analyzed after all lenses are installed in the optical system. Identifying a "bad" lens can require a lot of time and effort. These costs are even higher for systems and objectives with multiple lenses. Needless to say, the spectral performance of the complete lens objective also needs to be evaluated.

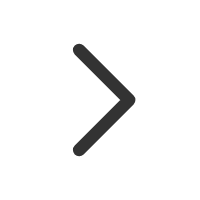

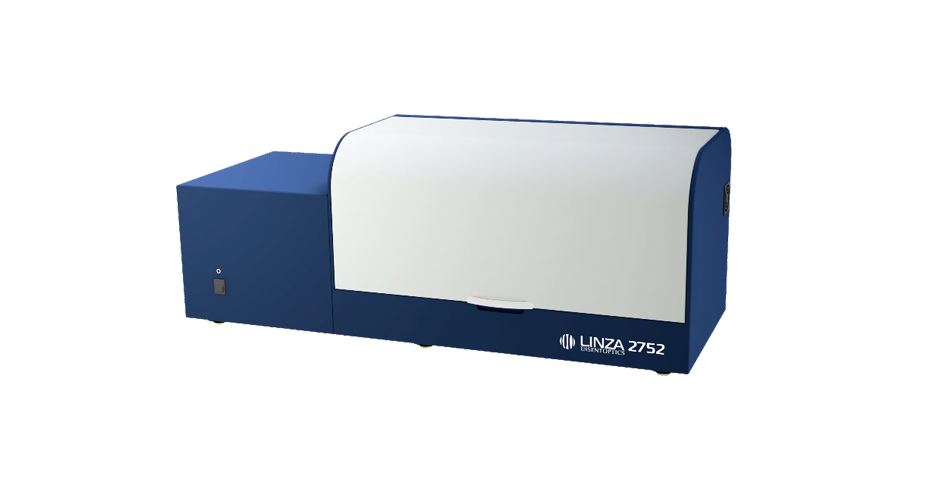

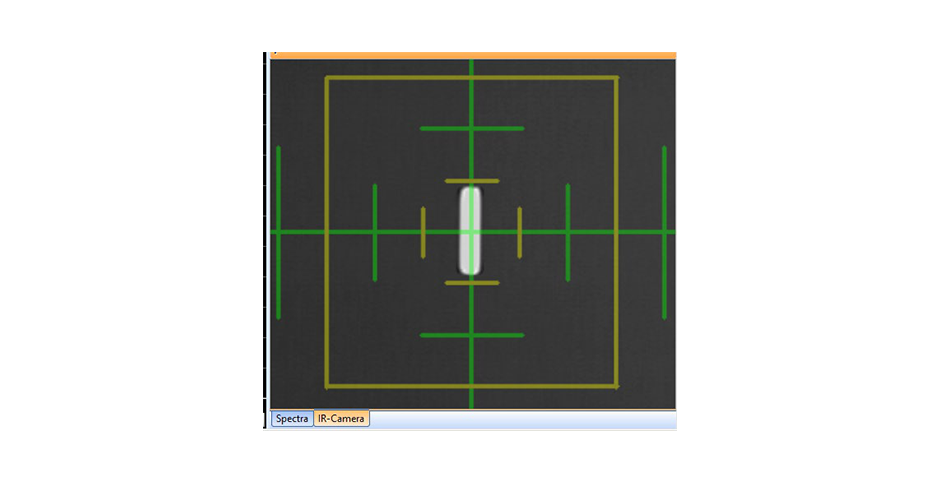

The LINZA 2752 spectrophotometer effectively addresses these challenges in on-axis transmission measurements of MWIR lenses and objectives. With its large compartment and sliding detector, single lenses with diameters from 10 mm to 150 mm can be successfully measured, as well as complete lens assemblies with end-to-end lengths of up to 680 mm.