Ultra-precision Coordinate Measuring Machine

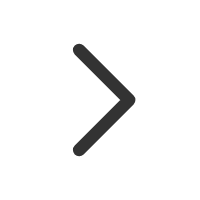

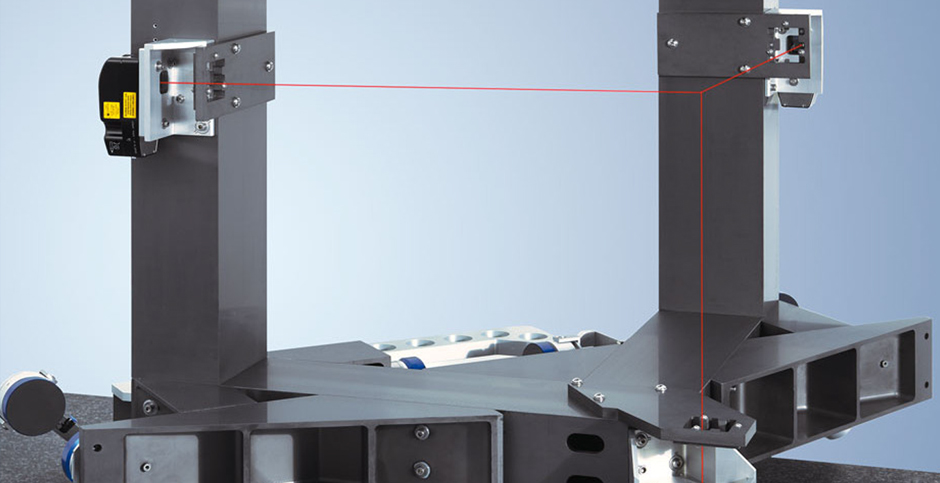

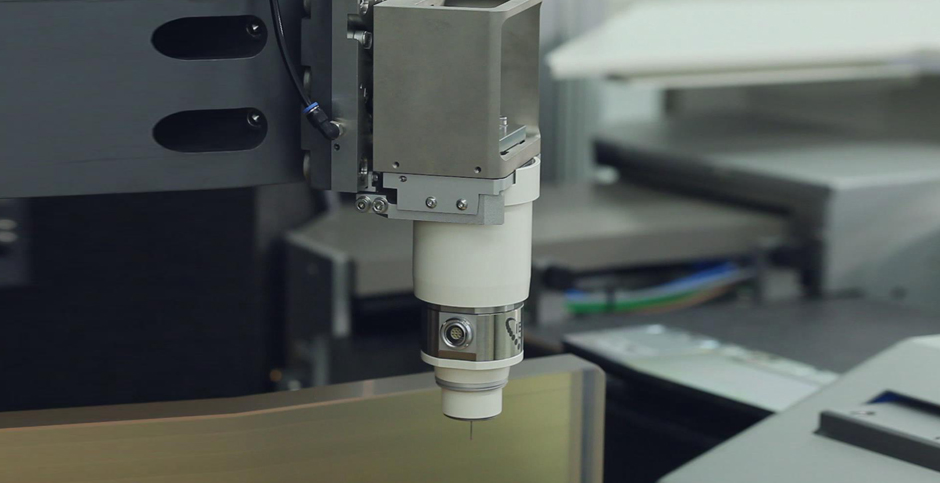

ISARA400 is a multi-probe 3D coordinate measuring machine that can achieve nanometer-level measurement of large-caliber and complex workpieces (free-form surfaces). With the unique omnidirectional probe technology, ISARA400 can also measure the geometric shape of the workpiece, including planes, holes and curved surfaces, and has an accuracy that other traditional coordinate measuring machines cannot match.

-

Product FeaturesMetrology tools for 3D measurement of complex surfaces and free-form optics with nanometer resolutionMeasurement uncertainty down to 50 nm (1D) in all three directionsCompared to similar CMMs, the measuring range has been significantly increased to 400 x 400 x 100 mmAbility to convert reference optical surfaces into mechanical referencesFully traceable measurementsMulti-probe instrumentation, enabled by a kinematic probe holderAll guides feature porous media air bearings for smooth, frictionless motion, ideal for 3D scanning measurements

-

Applications

- Surface measurement of large-aperture optical components

- Geometric shape measurement

- Optical dot array measurement of free-form surfaces

- Measurement of small array workpieces

- Surface measurement of (super) hemispheres

- Scanning measurement of aspheric mirrors and models

-

Specifications